Modernisation is no longer a luxury in today’s industries — it’s a strategic necessity. Facilities across Australia are upgrading infrastructure to remain competitive, reduce environmental impact, and improve overall efficiency. Whether it’s installing smarter automation, enhancing insulation, or replacing outdated equipment, every improvement counts.

But amidst all the upgrades, one critical system is often overlooked: the refrigeration compressor.

Despite being the beating heart of cooling and freezing operations, many facilities continue operating with compressors that are outdated, inefficient, and costly to maintain. If you’re planning a facility upgrade, now is the time to evaluate your compressor system — because ignoring it could cost you far more than you think.

Upgrading your plant or facility?

Don’t let outdated compressors hold back your progress. Taylor Refrigeration supplies and services high-performance, energy-efficient compressor systems tailored for modern industrial needs.

👉 Request a compressor upgrade consultation today

Why the Compressor Matters in Any Upgrade Plan

The compressor is one of the most energy-intensive components in an industrial refrigeration system. Yet, it’s often left untouched for years — even decades — simply because it still runs. However, running doesn’t mean performing optimally.

Here’s why compressors should be a priority in your facility upgrade:

- Energy Costs: Compressors can account for up to 60% of your refrigeration energy use. An older, fixed-speed unit is significantly less efficient than modern alternatives.

- Reliability: Aging compressors are more prone to breakdowns, often at the worst possible time, leading to costly downtime and potential product losses.

- Integration: Modern facilities rely on smart controls and integrated systems. Legacy compressors typically can’t “talk” to these new technologies.

- Environmental Compliance: With stricter emissions and energy standards, outdated compressors may no longer comply with current regulations.

Neglecting your compressor system during a facility overhaul can leave a gaping hole in your modernisation strategy — and limit your ability to achieve long-term savings and operational excellence.

Is It Time to Replace Your Compressor?

If you’re unsure whether your compressor needs replacing or upgrading, look for these common signs:

- 📈 Rising energy bills despite no significant increase in production

- 🔧 Frequent maintenance or costly repairs

- 🧊 Inconsistent cooling or inability to meet current demands

- ⚠️ Noise, vibration, or overheating issues

- 📉 No support for remote monitoring or integration with control systems

- 🛑 Non-compliance with modern refrigerants or energy standards

These indicators suggest your current system may be holding your facility back — and that a compressor upgrade could deliver rapid, measurable improvements.

Planning a plant-wide upgrade or expansion?

Let Taylor Refrigeration help you assess your compressor’s role in your modernisation roadmap.

👉 Book a system evaluation with our refrigeration experts today.

The Benefits of Modern Compressors in Today’s Industrial Facilities

Modernising your refrigeration system — particularly the compressor — delivers a host of tangible benefits:

✅ Energy Efficiency

- Variable Speed Drives (VSDs) allow compressors to match output with real-time cooling demand.

- Enhanced part-load performance minimises wasted energy.

- Newer compressor designs offer reduced friction, improved cooling, and tighter tolerances — all of which help reduce power consumption.

✅ Smart Control Integration

- New compressors feature onboard controllers with digital displays, alarms, and remote diagnostics.

- Seamless integration with building management systems (BMS), SCADA, or IoT platforms.

- Enables predictive maintenance and performance optimisation through live monitoring.

✅ Improved Reliability and Lifespan

- Fewer mechanical faults and longer service intervals

- Better materials, lubrication systems, and manufacturing tolerances reduce wear

- Diagnostics help prevent small issues from becoming costly failures

✅ Regulatory Compliance

- Most modern compressors meet or exceed Australia’s energy and refrigerant standards.

- Compatible with newer, low-GWP refrigerants for improved environmental performance.

- Helps meet HACCP, EPA, and other industrial standards.

✅ Lower Operating Costs

- Reduced energy bills, fewer repairs, and less unplanned downtime

- A compressor upgrade can often pay for itself within just a few years

- Lower total cost of ownership (TCO) over the compressor’s lifespan

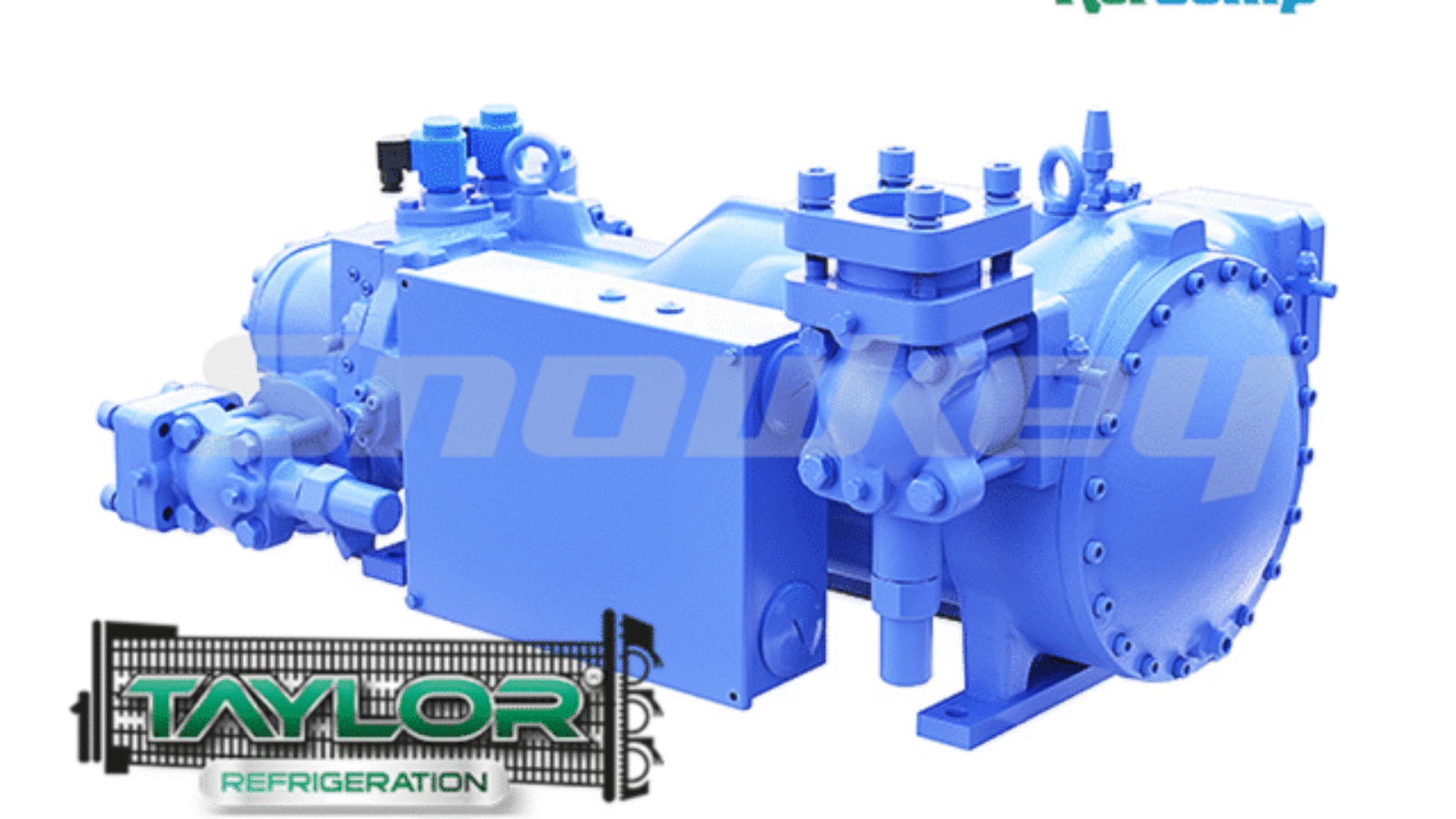

Featured Technology: RefComp Industrial Compressors

When it comes to choosing a reliable, efficient compressor for industrial applications, RefComp stands out as a global leader. With decades of innovation and performance behind the brand, RefComp compressors are designed to meet the demands of modern industrial refrigeration.

🔷 RefComp Screw Compressors

- High-capacity performance for continuous-duty applications

- Low vibration and reduced noise for improved workplace comfort

- Excellent efficiency across full and part-load conditions

🔷 RefComp Reciprocating Compressors

- Suitable for fluctuating load requirements and smaller plant setups

- Robust, time-tested construction with enhanced reliability

- Energy-efficient and easy to maintain

Why RefComp?

- Modern, modular designs

- Advanced built-in controls and diagnostics

- Long-lasting performance under tough industrial conditions

- Trusted in industries such as food processing, cold storage, logistics, and manufacturing

Why Choose Taylor Refrigeration?

Taylor Refrigeration has built a reputation as one of Australia’s leading suppliers and service providers in industrial refrigeration. As an official distributor of RefComp compressors, we offer:

- ✅ Expert advice on the best upgrade path for your facility

- ✅ Supply and installation of modern, energy-efficient compressors

- ✅ End-to-end support, including design, commissioning, and maintenance

- ✅ Rapid local service and a wide range of parts available in-region

- ✅ Experience across key industries including seafood, dairy, beverage, meat, and pharmaceuticals

Whether you’re upgrading a single plant or rolling out improvements across multiple sites, Taylor Refrigeration can help you modernise with confidence.

A Smart Facility Starts With a Smart Compressor

In the race to modernise, it’s easy to focus on the most visible or glamorous upgrades — automation, digital dashboards, or high-efficiency lighting. But none of those systems can perform optimally if your core refrigeration infrastructure is stuck in the past.

The compressor may not be flashy, but it is absolutely foundational. A modern, efficient, and reliable compressor — like those from RefComp — can unlock substantial energy savings, improve reliability, and support your facility’s long-term growth.

And with Taylor Refrigeration by your side, you gain a knowledgeable partner who can help you implement the right solutions with confidence.

✅ Ready to Upgrade Your Compressor System?

📞 Book a consultation online to get started.